The influence of humidity on crystal vibration performance and the test of insulation resistance at high temperature and humidity.

Humidity can affect the stability and performance of crystal vibration to a certain extent. For applications that require high accuracy and stability, such as communications, precision measurement or control systems, the effect of humidity on the crystal oscillator may require special attention. When designing such applications, consideration is given to moisture resistance, sealing or the selection of special materials to reduce the impact of humidity on the performance of XtalTQ’oscillators.

Effect of humidity on crystal vibration:

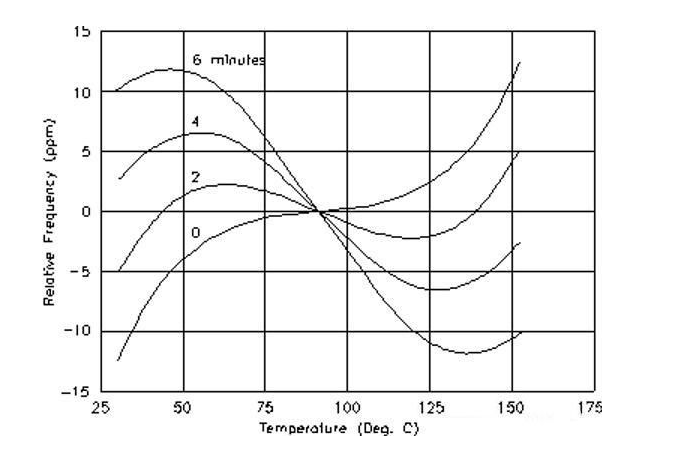

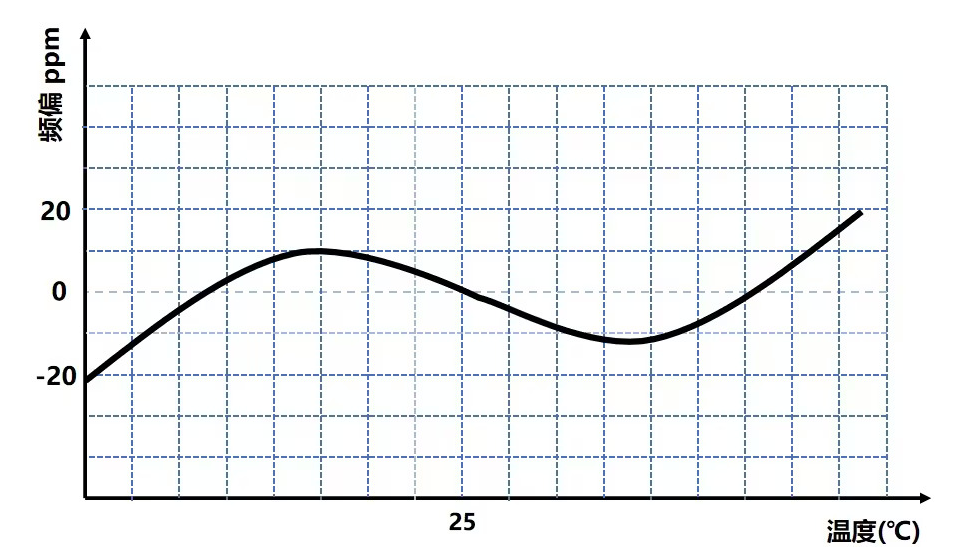

1. Frequency drift: Humidity changes may lead to small changes in crystal frequency. Water molecules adsorb or repel on the oscillator surface of the crystal oscillator, which may cause small changes in the crystal frequency. Humidity increases the stray capacitance of the peripheral circuit of the crystal, about 8ppm/1pf, and increases the error.

2. Reduced stability: Changes in the crystal element surface caused by humidity may lead to frequency instability, affecting the accuracy and reliability of the crystal oscillator.

3. Aging and life: In high humidity environments, crystal components may accelerate aging. This may shorten the life of the crystal oscillator or reduce its performance.

4. Internal corrosion: The wet environment is easy to cause corrosion of the internal materials of the crystal oscillator, which affects its performance.

5. Crystal vibration storage:In the process of crystal vibration storage and use, strict control of air humidity is very important. The moisture will accelerate the oxidation of the crystal metal pad, leading to the virtual welding of the crystal pin or pad in the subsequent welding process, which may cause the crystal oscillation instability or vibration stop.

Recommended storage humidity range: Maintain relative humidity in the range of 30% to 75% to help avoid adverse effects of humidity on crystal vibration.

Precautions: Avoid rain or direct sunlight

Process of insulation resistance testing under high temperature and high humidity conditions:

1. Sample preparation: Select a representative sample of insulation material and carry out surface treatment to ensure that the surface is clean, free of impurities and damage.

2. Set test conditions: According to the standard requirements, set test temperature, humidity, pressure and other conditions to ensure the accuracy and comparability of test results.

3. Measure volume resistance: Put the sample in the test equipment, apply current through the current source, measure the voltage at both ends of the sample, and calculate the volume resistance value.

4. Measure the volume resistivity: Calculate the volume resistivity according to the measured volume resistance value and the size of the sample.

5. Analysis results: Comparing the volume resistance and volume resistivity at different temperatures, analyzing the trend of electrical properties of insulation materials.

If tested in a high humidity environment (air relative humidity is greater than 80%), the leakage current of the external insulation surface of the tested equipment may increase significantly, resulting in a low insulation resistance value, which cannot accurately reflect the actual condition of the insulation inside the tested equipment. At this time, the shielding method can be used to reduce the influence of humidity on the test results. The specific operation method is to use a fine copper wire or fuse to tightly wrap 2 to 3 turns on the outer insulating surface of the test object near the high voltage end of the megohm meter (as close as possible), and then connect to the shielding terminal of the megohm meter, so that the leakage current on the outer surface does not flow through the indicating head of the megohm meter. In this way, the adverse effects of excessive humidity can be greatly reduced and ignored.

High temperature and high humidity (charged) environment: being in a high temperature and high humidity environment for a long time, especially in the case of charging, may accelerate the aging and performance attenuation of crystal components. This can lead to frequency instability and reduced accuracy.

Insulation resistance testing: During insulation resistance testing, a voltage or current may be applied to the crystal oscillator. In this case, care should be taken to prevent voltage or current from causing damage to the crystal element, so as not to affect its performance and stability.

+86-28-85980596

+86-28-85980596  sales@xtaltq.com

sales@xtaltq.com +86-28-85980596

+86-28-85980596

sales@xtaltq.com

sales@xtaltq.com

No.666 Shaojia Street, Shuangliu District, Chengdu, China

No.666 Shaojia Street, Shuangliu District, Chengdu, China